DryCleaner™ Furnaces

DryCleanerTM Furnaces

For parts with up to 2% combustibles

Maximum 800°F (427°C)

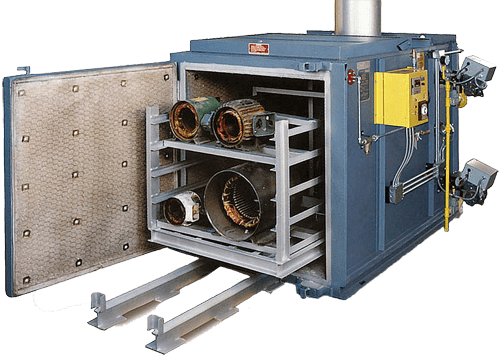

As an industrial drying oven manufacturer, PCPC designs DryCleaner furnaces that are equipped to safely and economically remove small amounts (1 to 2% by weight) of varnish, insulation, epoxy, paint, oil, grease, plastics, etc. primarily from electric motor stators, transformers, end bells, engine blocks, and other metal parts.

Industrial Dry Cleaning Oven Process

DryCleaner Furnaces (industrial dry cleaning oven) clean metal parts by the process of pyrolysis, which is literally "burning without flame" or the chemical decomposition of organic material by the action of heat. The material on the metal parts must be cured, meaning no solvent vapors are present. During the industrial oven cleaning process, organic material is driven off as smoke leaving only a thin layer of ash, which can be easily removed with a water rinse. The smoke is then processed through a 1400°F afterburner, consuming the remaining pollutants and exhausting into the atmosphere primarily water vapor and CO2 which is invisible, odorless and harmless. DryCleaner industrial drying ovens use a simple water spray "fire extinguisher" system based on furnace temperature to prevent ignition or over-heating.

Key Features & Benefits of the Industrial Dry Cleaning Oven

| Damage Prevention | The water spray system controls the rate of smoke emissions during the process to ensure ignition or over-heated based damage is prevented. The primary burner helps to drive off volatile materials as smoke and the flame never touches the parts |

| Pollutant Removal | The afterburner helps to burn the smoke and leaves only invisible, odorless and harmless water vapor and CO2 to leave the exhaust |

| Air Pressure Reduction | Explosion relief doors in the furnace relieve excess pressure and closes to prevent air from reaching combustible materials |

Standard Features of DryCleaner™ Furnaces

- The Primary Burner heats the cleaning chamber to 800°F (427°C). Volatile materials are driven off as smoke. The burner flame is confined to the combustion chamber never touching the parts.

- The Afterburner operating at 1400°F (760°C) for ½ second burns the smoke consuming the pollutants, leaving only invisible, odorless and harmless water vapor and carbon dioxide to exit the exhaust stack.

- Explosion Relief Door(s) automatically opens to relieve excess pressure then closes preventing air from reaching combustible materials.

- Diagnostic Panel indicator lights reflect the operational status of the oven and its controls. Indicator light failure pin-points the problem.

- See all Features & Specifications

Contact Pollution Contol Product Co., an industrial furnace manufacturer, to learn more about our DryCleaner furnaces!